| Today |

| Workshops |

| Audio/Video |

| Electronics |

| Carputer |

| Misc |

| Other Garages |

| Contact Us |

| RainyDayGarage... |

||

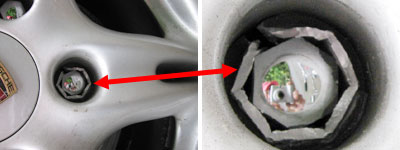

We had removed all of the chrome wheel bolts and replaced them with the rusty ones before bringing the tires to the installer to get them flipped around (see Porsche Puzzler). Unfortunately, it then rained for a week. Today was the first chance we had to put the chrome bolts back on. We thought it would be a 10 minute job...six hours later, we were finally finished. What happened??? Well, we were down to the last three bolts when the SoftSocket we were using failed.

It failed in such a way that the top piece of the socket became firmly wedged between the wall and the bolt. We could drive it in this condition with no problems, but if we ever had to take the tire off, it would be impossible. There was no way we could leave things in this condition.

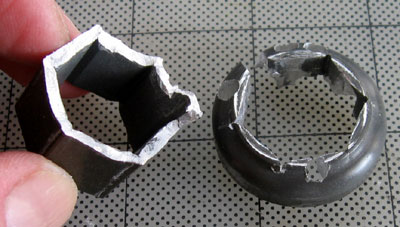

We thought...what a great opportunity to test out the Dremel stand! So we got out all the gear and went at it. About an hour into the job we realize it would take a lot of grinding bits to work the wedged piece down. What we needed was to grind the wedged piece enough so the head of the bolt is exposed. If we could turn the steel bolt we would strip the inside of the lodged piece and free it that way. After another hour of trying we were still not making much progress. There was just too much metal for the strategy to work. Someone suggested we drill out the piece to weaken it...brilliant! A couple of hours and a few broken bits later, the approach worked. We are able to turn the bolt and strip the inside. In order to get the bolt freed and remove the trapped piece, we had to take the wheel off and tap everything out. The SoftSocket is made of two pieces, a steel socket with a softer metallic insert. The insert extends out about a quarter of an inch.

We believe it was the top section that failed first. From looking at the pieces, we believe the crack started from the top and caused the top to rip away from the remaining section that was still in the socket.

In the photos above, you could see the drilled sections (left) and the stress failure (right). Below is a pic of both the insert and the top piece.

After thinking about it some more, we are pretty certain the failure was due to the design. With a bolt in, it is pretty clear that most of the torque when the bolt is turn will be borne by the top piece. Sooner or later it will rip and tear away from the lower section. We are not ruling out user error either. Maybe we didn't insert the socket deep enough? Maybe there was a problem with the torque wrench? All we know is we are finally ready for Summer!

Our final question was should we get a new soft socket for the chrome bolts? It then dawned on us to just reuse the broken insert by flipping it around. This "improved" soft socket will still fit the bolts and it should not have the same problem as the original design as the softer metal is now completely surrounded by steel. Somebody should just sell a set of inserts...then every socket can be a smaller "soft socket"! UPDATE: We were informed that the material used in the SoftSocket is made of the "hardest aluminum that exists and it is further hard anodized to make it harder and it has recessed corners so as not to touch the corners of a bolt. Then it is impregnated with teflon to give it a soft touch for those lug nuts or bolts that have fragile finishes like polished aluminum, chrome plated steel or aluminum, gold plated lugs or black anodized lug nuts " We showed the SoftSocket above with a rusty bolt because the chrome ones are on the Boxster and we didn't want to pull it off just for the photo. It should also be noted that we only used the SoftSocket with the chrome bolts and NOT the rusty OEM bolts...we used our regular steel sockets for them. According to Boothe Design, they have sold a few thousands of these SoftSockets over the past 20 years and we were the first to completely destroy one in this manner. Clearly other folks know how to use this stuff a LOT better than us! Email us your thoughts on what we did wrong...we would hate to keep trashing our tools. |

Boothe Design Chrome Wheel Bolts |

|

The problem is our wheel bolts always get REALLY rusty over the Winter. We clean and paint them every Spring, but can't seem to keep the rust from coming back.

This year we decided to try something new. We have decided to replace all of the rusty bolts with these gorgeous bolts from Boothe Design. The bolts are beautiful, but think twice about the SoftSocket :-) Reviews: 1. FirstLook 2. FirstUse 3. InTheWild Bolt removal Summary: 1. Difficulty - hard 2. Time - 6 hours 3. Tools - drill, bits, patience 4. Cost - one beautiful day Related Reviews:

|

||